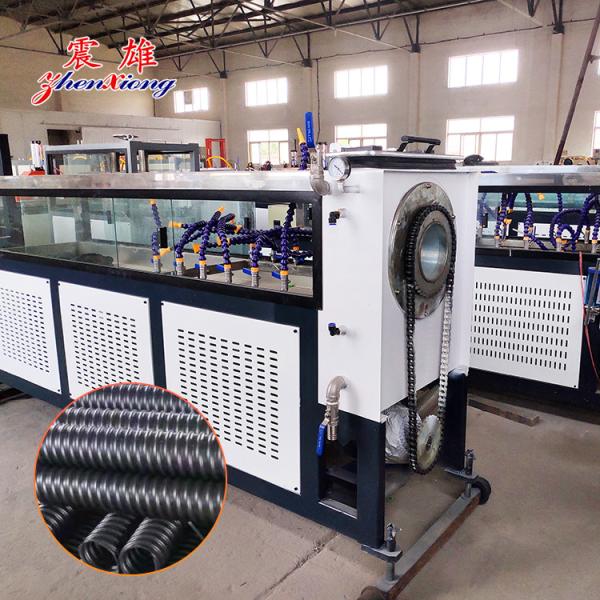

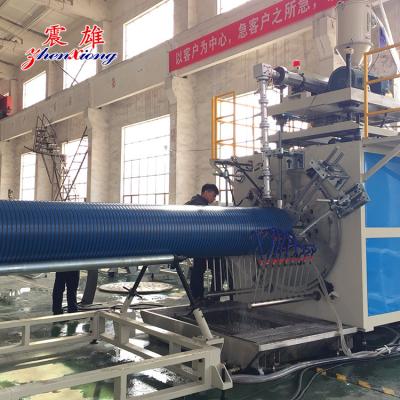

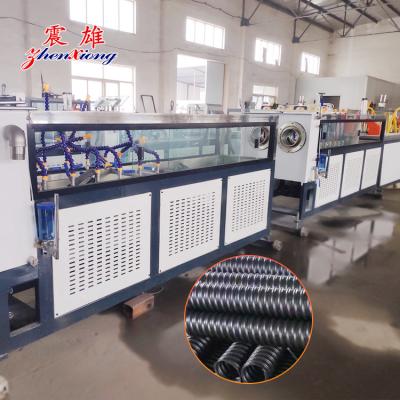

The HDPE prestressed spiral corrugated pipe equipment mainly uses high-density polyethylene (HDPE) or polypropylene (PP) as raw materials, adopts advanced production technology for one-time molding, has fast production speed, and greatly improves production efficiency.

Core advantages:

●The HDPE prestressed spiral corrugated pipe equipment is equipped with a single screw extruder designed for professional polyolefin materials, which has the characteristics of high-speed extrusion and low-temperature plasticization.

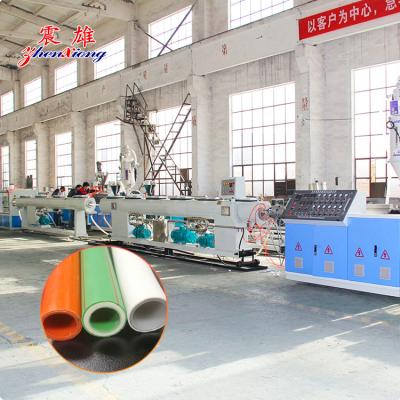

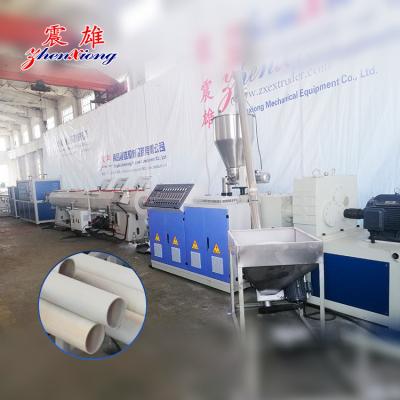

●Suitable for extrusion of polyolefin materials, capable of extruding spiral reinforced tubes of different specifications for various purposes.

●The HDPE prestressed spiral corrugated pipe equipment is specially designed with a separate mixing screw and spiral structure head, with a reasonable flow channel and smooth inner and outer surfaces of the pipe.

●The design of HDPE prestressed spiral corrugated pipe equipment with low melting temperature results in lower internal stress and stronger pipe performance.

●The box is made of stainless steel.

●Vertical movement motor adjustment, three-dimensional adjustment can be achieved up, down, left, right.

●The water pump and special spray head design have good spray cooling effect.

Product application scope:

It has the advantages of good sealing, no water seepage or slurry leakage, high ring stiffness, low conflict coefficient, aging resistance, resistance to electrical corrosion, good flexibility, not easily broken by ramming rods, and more convenient construction connection.

Mainly used in the construction of large-span tensioning projects such as highways, railways, bridges, slopes, and high-rise buildings.

| Extruder Model | Single Screw | Weight | 3 tons |

| Voltage | 380V 50Hz | Cooling method | spray cooling |

| Dimensions | Length 20 meters | Warranty | 1 year |