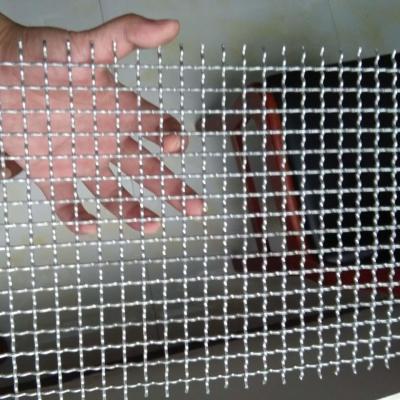

This specification is also referred to as "Vibro Type Weave". Efficient and long wearing in a variety of applications Providing a level, smooth surface, the Smooth weave employs a type of rigidity interlocked crimp that insures maintenance of accurate, uniform openings. When used in the correct application, because of the level weave, there is considerable reduction of friction from material passing over the screen and, in many cases, far less wear from abrasion than in screens made with surface crimps.

Apparel & Textile Machinery

(75900)

Building Material Machinery

(55852)

Cleaning Equipment

(104054)

Electronics Production Machinery

(39881)

Energy & Mineral Equipment

(127869)

Engineering & Construction Machinery

(401378)

Environmental Machinery

(35590)

Food & Beverage Machinery

(97353)

Industrial Compressors & Parts

(28499)

Industrial Robots

(3603)

Industry Laser Equipment

(44115)

Machine Tool Equipment

(129643)

Machinery Accessories

(202994)

Machinery Service

(996)

Metal & Metallurgy Machinery

(69132)

Packaging Machine

(102444)

Paper Production Machinery

(29371)

Language

Français

Русский язык

Español

日本語

Português

Show all machinery categories

Apparel & Textile Machinery

(75900)

Building Material Machinery

(55852)

Cleaning Equipment

(104054)

Electronics Production Machinery

(39881)

Energy & Mineral Equipment

(127869)

Engineering & Construction Machinery

(401378)

Environmental Machinery

(35590)

Food & Beverage Machinery

(97353)

Industrial Compressors & Parts

(28499)

Industrial Robots

(3603)

Industry Laser Equipment

(44115)

Machine Tool Equipment

(129643)

Machinery Accessories

(202994)

Machinery Service

(996)

Metal & Metallurgy Machinery

(69132)

Packaging Machine

(102444)

Paper Production Machinery

(29371)