GCE 1500V ESS High voltage lithium battery management system BMS quality long life solar energy storage system

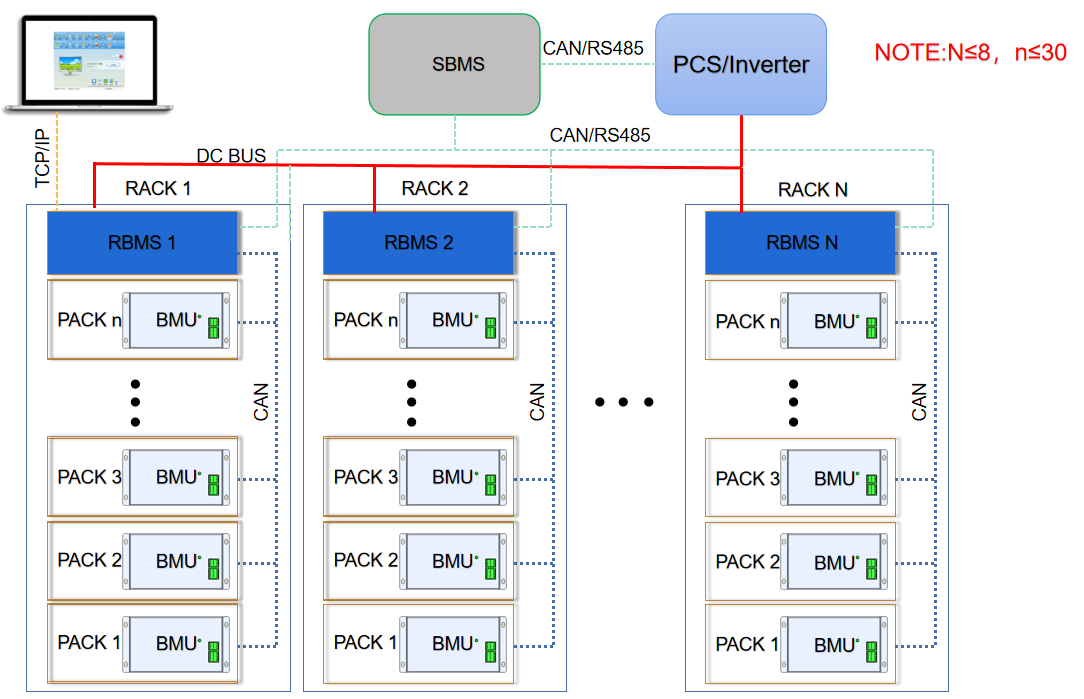

Product system overview

Description

A battery management system (BMS) is an electronic system that monitors and controls the charging and discharging of a battery. It is typically used in applications where multiple batteries are connected in series or parallel, such as electric vehicles, renewable energy systems, and backup power systems.

Application scenarios

◎ PV power plant storage

◎ Island off-grid energy storage

◎ optical storage charge integration applications

◎ UPS power supply

| | Rated current | 200A |

| operation voltage | 300V-1500V |

| Power consumption | ≤15W |

| Current sampling accuracy | 1%FSR |

| Insulation withstand voltage | 4000VDC <1mA 1min |

| Protection level | IP20 |

| Size(W*H*D) | 482*180*500(mm) |

| New Weight | ~22Kg |

| Communication

Interface | Communication port with BMU | CAN |

| Communication port with UPS | RS485/CAN |

| Communication port with SBMS | RS485/CAN |

| Communication with monitoring software | Ethernet |

| Basic Function | Battery charge & discharge management | Available |

| Battery temperature management | Available |

| IAP Upgrade | Available |

| System protection parameter setting | Available |

| Short circuit protection | available(1500V 20KA 20ms) |

| Pre-charge function | Available |

| Parallel circulation control | Available |

| Event record | Available(5000) |

| Dual power supply | Available(Battery + municipal power

supply, municipal power in priority) |

| Optional function | Insulation detection | Suitable for systems with voltages above 300V |

| HMI display | 3.5 inches, 7 inches optional (external)

(optional) |

| Stand-alone or parallel function | Set up before leaving the factory |

| Dry contact | Maximum 2 dry contact outputs (optional) |

| Color | RAL7035 Grey white |

| Installation method | Suitable for standard 19-inch rack installation |

| Incoming and outgoing wire method | Front side in and front side out. |

| Operating ambient temperature | -20℃~60℃ |

| Operating ambient humidity | 5%~75%RH |

| Comply with National standards | GB/T 16935.1 GB/T 17626.2 GB/T

17626.5 |

| Certification | Comply with CE certification standards |

RBMS Interface Description

| No. | Name | Description | Precautions |

| 1 | B+ B- | Connect to the battery's total positive and total negative | Quick plug connection |

| 2 | P+ P- | Connect to the charging equipment (PCS) or DC bus | Quick plug connection |

| 3 | AC Input | The municipal power supply input port must be taken from the UPS/Inverter output side | 85~264VAC 1A max |

| 4 | ON OFF | ON: The circuit breaker is ON.

OFF: The circuit breaker is disconnected | When the handle of the circuit breaker is in the trip state in the middle position, it needs to be turned OFF before it can be closed again. |

| 5 | D1 D1 D2 D2 | Two dry contact output reserved | The default D1 is charging prohibited, D2 is discharging prohibited |

| 6 | Start | DC start button: start the RBMS system By taking power from the battery side. | The system is connected to the battery, and after the circuit breaker is closed, press and wait until the light is on to indicate

that the system is on |

| 7 | System | System status indicator | System normal: Green Alarm: yellow light Self test failure and protection status: red light

Charging: green light flashes

Discharge: red light flashing

Self checking: red and green flashing alternately

Pre-charging: yellow flashing |

| 8 | 1 2 4 8 | ID allocation: When multiple RBMS are

used in parallel, the ID are allocated by

setting the DIP switch. Must start at 1 | There are 4 DIP switches in total, supporting up to 15 RBMS in parallel

1 ON: ID+1

2 ON: ID+2

3 ON: ID+4

4 ON: ID+8 |

| 9 | TCP/IP | The RBMS host computer system software can be connected to the PC through the network cable | Network cable standard CAT5 or above, crossover cable or straight cable can be

used, the line sequence can be according

to the standard TIA-586A or TIA-568B |

| 10 | T-CAN

T-485 | Terminal matching resistance setting

during can and 485 communication

Setting Description: (120R), on is valid | In parallel application, only the last one needs to be set. In stand-alone application, it can be used flexibly according to site conditions (interference, communication distance, etc.). |

| 11 | COM-IN

COM-OUT | RBMS external communication port: When multiple RBMS in parallel: Communication with SBMS

When RBMS Stand-alone: communicate with UPS/PCS external devices | The shielded twisted-pair cable harness

must be used randomly. The cable

sequence is defined in the cable harness

label |

| 12 | GND

HMI-B

HMI-A

24V | 1.For external display connection

2.For powering SBMS | Please connect the display screen according to the silk screen sequence |

| 13 | BMU-OUT | Communication interface with BMU | Cascaded communication between BMU |

| 14 | ㊤ | RBMS chassis ground | Must be grounded, and the grounding

resistance is less than 1Ω |

1024V 200Amp 4U RBMS

Communication protocol : Rs485,CAN, LAN

* 4U standard 19inch case

* Efficient, stable and reliable

* size:W485*H180*D550mm

Accessories

8S-24S BMU(Slave)

8S-24S BMU has 8pcs of tempreture sensors, Fan voltage 48V(17S-24S 12V), voltage detection range 0-5V,12V power supply,consumption less 20mA, CAN2.0 B communication

Wire harness-Signal acquisition wire

18 Pin+20Pin wire, standard length is 600mm,900mm,1200mmtempreture sensor. wire: standard length is 600mm,900mm,1200mm

Fan wire: 600mm

Wire harness-communication wire

Communication wire is connecting from master BMS to each BMU with cascade connection, the last port is for terminal resistance.wire: standard length is 180mm,300mm,600mm