Alloy Profile 4 Axis CNC Machining Center

Drilling Milling Tapping Cutting End Milling on Alu Profile

Automatic Tool Changer with 12 sets tools

Spindle rotation from 90 to +90 degrees at any angle

With RTCP function

Double working range

The four machining centre with four axes has been designed to perform drilling and milling operations on aluminium or metallic profiles. Because of the answers utilized in its construction, WSJ4 is appropriate to system massive phase profiles. The 24,000 rpm, 9.6 kW electrospindle lets in elimination of a great quantity of chips and excessive machining speeds.

1. Main Feature

● The system can understand the clamping of uncooked substances at one time, and in line with the processing needs, it may entire the cutting, milling quit face tenon, milling key hollow slot, going for walks trough, air strain stability hollow, set up hollow and different multi-manner processing to fulfill customers' necessities for doors, windows, curtain walls, and solar rooms. , Personalized customization of commercial aluminum profiles.For quite a few aluminum, copper, PVC, commercial profiles and different complicated components processing.

● The system is ready with an commercial numerical manipulate machine, committed CAD-CAM enhancing software program for 3-dimensional modeling display, automated device setting, which could optimize the tour path. It can entire non-stop automated milling of various specs and sizes of profiles, with effective functions. CAD drawings may be imported into the machine for handy and simple, and may be equal to home and overseas doors, windows, and curtain wall machine software program.

●It is appropriate for the processing of complicated components which include diverse aluminum, copper, PVC, commercial profiles, constructing curtain walls, and solar rooms.

● The single-arm body shape with transferring beam and transferring column is adopted, which makes the operation greater strong and improves the processing pressure of the system device.

● High-first-rate bus servo motors, ball screws, linear courses and bearings are used to make sure that the gadget has excessive processing accuracy, excessive balance and reliability. The feed motion is pre-stretched to make sure the stableness of the machining accuracy.

● This system adopts excessive-velocity electric powered spindle imported from Italy, which could entire the processing of any perspective on the alternative 3 facets besides the bottom. Vertical disc kind device magazine (12 positions).

| Spindle Power | 9KW |

| X-way range | 6500mm |

| Y-way range | 1500mm |

| Z-way range | 600mm |

| C axis rotation range | ±90° |

| Spindle speed | 24000r/min |

| Tool storeroom type | Dis type |

| Tool magazine capacity | 12 |

| Lubricating system | Automatic lubrication system |

| X-way moving speed | 0〜55m/min |

| Y/Z-way moving speed | 0~40m/min |

| Air pressure | 0.6~0.8MPa |

| Weight | 8800x2500x2800mm |

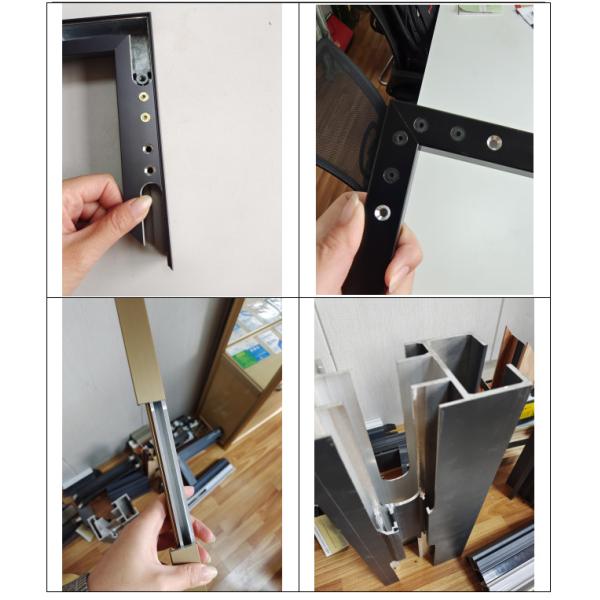

2. Samples Holes After Working:

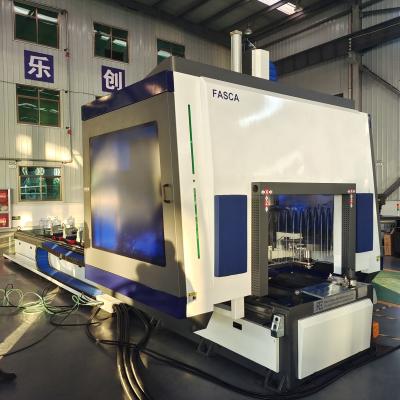

3. Machine Details

4. Provide Service:

1. Provide free training when come to factory study

2. If need engineer go to oversea training: Client afford transportation and accommodation, Engineer salary is 100USD/Day

Because of Covid-19, we can also provide:

1. Before delivery: Machine operate manual, program software user manual as well as Chinese and English videos

2. Before delivery: Face to face video training online between your operator and our engineer (Can speak English)

3. After delivery: Will video guild you how to install and adjust machine. Also we can online control your machine to show you how to work.

Contact Us For More Information:

4. Questions:

4.1 Why called 4 Axis CNC Machining Center?

4.2 How this 4 Axis CNC Machining Center working?

4.3 Why have to match RTCP function?

Answers: For all those answers, pls contact us, We will sent you machine videos. Thanks