Vibration Testing : The Ultimate Guide to Vibration Testing for EV Battery Packs

According to the Ministry of Public Security, as of June 2022, the number of new energy vehicles in China exceeded 10 million, accounting for 3.23% of the total number of vehicles. In recent years, to save energy and protect the environment, the state has strongly supported the development of new energy electric vehicles, formulating a series of subsidy policies for new energy electric vehicles and management systems for automobile enterprises. Hybrid and pure electric vehicles have become key research and development focuses for companies. Several European countries have already developed plans to phase out fuel vehicles, making electrification the future trend in automobiles. The power battery system is the core component of electric vehicles, and its reliability directly affects the safety and reliability of the entire vehicle. During vehicle operation, the power battery system is constantly subjected to vibration loads, making vibration resistance an important evaluation criterion. Vibration testing is an essential method for assessing the mechanical reliability of power battery systems. This article primarily introducing the vibration testing methods of power battery systems.

Vibration Testing : The Ultimate Guide to Vibration Testing for EV Battery Packs

1. Vibration Testing

1.1 Sine Vibration

1.2 Random Vibration

1.3 Mixed-mode Vibration

2. Comparison of Battery System Vibration Standards

2.1 International Standards

2.2 Domestic Standards

3. Vibration Testing of Power Battery Systems

3.1 Vibration Table

3.2 Test Fixtures

3.3 Sensor Placement

3.4 Test Monitoring

3.5 Vibration Testing of a Power Battery System

Latest Reviews

1. Vibration Testing

Vibration refers to the oscillatory motion of an object relative to its equilibrium position. It is generally characterized by functions such as displacement, velocity, and acceleration that change over time. The main sources of vibration for power battery systems include road surface irregularities and motor rotation imbalances. The main impacts of vibration on products are:Structural damage, such as deformation, cracks, and fractures of components.Malfunctions in performance, such as system instability.Damage to process features, such as loose bolts and detached welds.

Based on the different load spectrums applied, vibration testing can generally be divided into the following types:

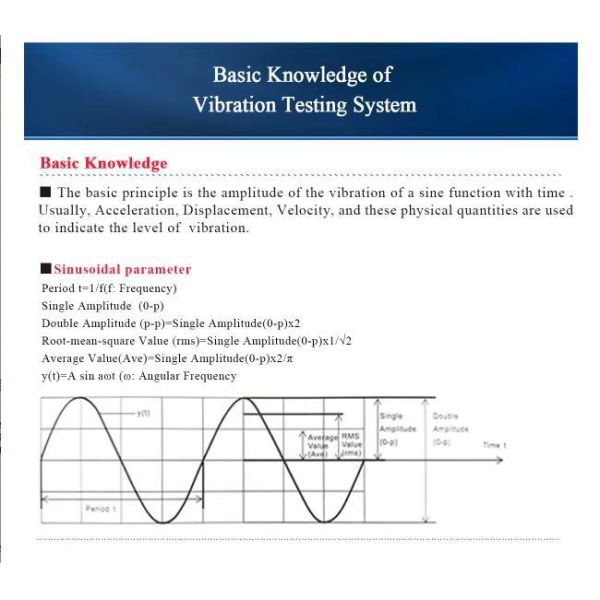

1.1 Sine Vibration

Sine vibration is a type of vibration that changes according to a sine (or cosine) function over time, exhibiting periodicity. Sine vibration can be divided into two types: fixed-frequency vibration and sweep-frequency vibration. A test where the vibration frequency remains constant is called a fixed-frequency vibration. This type of vibration generally simulates the vibration caused by fixed-speed rotating machinery or the vibration at the natural frequency of a structure. Fixed-frequency vibration is mainly used to test the resistance to resonance frequency vibration and predetermined frequency vibration. Sweep-frequency vibration involves changing the frequency according to a specific rule, and it can be categorized into linear sweep and logarithmic sweep based on the sweep speed. The frequency change in linear sweep is linear, meaning it covers a certain number of hertz per unit time, expressed in Hz/s or Hz/min. This type of scanning is used to fine-tune the resonance frequency in tests. Logarithmic sweep frequency changes according to a logarithmic pattern, with units like Oct/min or Oct/s, where “Oct” represents an octave. Logarithmic scanning means that the number of octaves covered in the same amount of time is the same, resulting in slower sweeps at low frequencies and faster sweeps at high frequencies. Sine vibration test conditions include the test frequency range, test level (acceleration amplitude), sweep speed and duration, and test direction.

1.2 Random Vibration

Random vibration⇱ is a type of vibration with an irregular time-domain waveform, where the instantaneous value at a given moment cannot be determined, and the waveform changes randomly over time. The vibrations encountered during transportation and actual use are mostly random vibrations, such as the vibrations generated when a vehicle travels on a road, vibrations caused by aircraft noise on the aircraft structure, and vibrations generated by atmospheric turbulence on wings. Therefore, random vibration testing better reflects the vibration resistance of products. Random vibration cannot be accurately expressed as a time function, so its amplitude and frequency cannot be determined at any moment. However, random vibration can be statistically expressed. It is usually described in the frequency domain, and the test conditions for random vibration testing (severity level) generally consist of the following four components:

Test frequency range (Hz): The frequency range refers to the frequency between the highest and lowest frequencies at which vibration effectively excites the product.

Power spectral density (PSD): Power spectral density describes the energy distribution of vibration per unit frequency.

Total root mean square acceleration (Grms): Grms is the integral of the PSD over the frequency range, representing the root mean square value, which is commonly used to control and detect test errors.

Test duration and direction.

1.3 Mixed-mode Vibration

Mixed-mode vibration generally involves the superposition of sine and random vibrations, such as random-on-random, sine-on-random, sine-on-random-on-random, and so on.

Vibration Testing for EV Battery Packs

2. Comparison of Battery System Vibration Standards

Vibration testing is a crucial method for evaluating the performance of power battery systems. Most testing standards for battery systems include vibration tests. The national mandatory standard GB38031⇱, issued in 2020, clearly defines the methods and requirements for vibration testing of power battery systems. The relevant standards for vibration testing of battery systems in both domestic and international contexts are as follows:

2.1 International Standards

USABC 1996 “Battery Test Manual for Electric Vehicles” is an early battery testing standard established by the United States Advanced Battery Consortium. The vibration test in this standard has been referenced by later standards such as USABC1999 “Abuse Testing Manual for Electrochemical Energy Storage Systems” and Freedom CAR “Abuse Testing Manual for Energy Storage Systems in Electric and Hybrid Electric Vehicles.”

SAE J2380⇱, developed by the Society of Automotive Engineers (SAE), includes a vibration test widely used domestically. J2380 refers to the USABC’s random vibration test to simulate the vibrations induced by road surface irregularities on batteries used in new energy vehicles, assessing their vibration resistance. The vibration test requirements of J2380 have been referenced by SAE J2929 and UL2580 from Underwriters Laboratories. This standard provides two optional vibration test levels, with different test durations for each level.

UN 38.3 is primarily used to simulate the vibration loads experienced by lithium batteries during transportation. The vibration test in this standard is conducted with sweep-frequency vibrations in the X, Y, and Z directions, and the vibration test level varies depending on the weight of the sample (12kg).

ISO 12405, established by the International Organization for Standardization (ISO), specifies the detailed testing requirements for power battery systems. The standard specifies that the state of charge (SOC) during testing should be 50%, and the test duration can be adjusted by increasing the number of test samples. This standard’s vibration test has been referenced in the early GB/T 31467.3-2015.

ECE R100-02 is the current standard used for European certification of new energy vehicles. The standard specifies a sweep-frequency vibration test at 7-50Hz, and the power battery system must complete a standard charge-discharge cycle after the sweep-frequency vibration.

2.2 Domestic Standards

GB/T 31467.3-2015⇱ is significant for standardizing the testing of automotive power battery systems in China. Its vibration test references ISO 12405, but adjusts the SOC to 100%. The standard specifies that the power battery system undergoes 21 hours of random vibration in the X, Y, and Z directions.

GB/T 31467.3-2015 Amendment No. 1 (2017). The vibration test requirements in GB/T 31467.3 are relatively stringent, with a low pass rate. Although companies can meet the standard’s requirements through product improvements, this often results in excessive structural strength and increased costs, which contradicts the principle of vehicle lightweighting. A large amount of real vehicle test data also shows that real vehicle vibration loads are relatively mild. Therefore, in 2017, the vibration requirements of GB/T 31467.3 were revised in Amendment No. 1, referencing ECE R100-02, which specifies a 3-hour sweep-frequency test in the vertical direction for power battery systems.

GB 38031⇱ is China’s first national mandatory standard in the field of automotive power batteries. It will replace GB/T 31467.3, standardizing the testing requirements for automotive power batteries. The vibration test in this standard specifies that the SOC of the battery pack or system should not be lower than 50%, and the vibration test load varies depending on the type of vehicle. The test consists of random vibration and fixed-frequency vibration parts. The PSD of the random vibration is based on a large amount of actual measurement data from different vehicle models on the road, making it closer to the actual load conditions of new energy vehicles in China. Compared to GB/T 31467.3 and its Amendment No. 1, the vibration test in GB 38031 is more reasonable.

The vibration standards for power battery systems in domestic and international contexts are both related and distinct. Many of these standards are derived from ISO 12405 and SAE J2380, but the test conditions (such as frequency range and test level) and sample requirements differ among them. A comparison of the main parameters of each standard is shown in Table 1.

Vibration Testing for EV Battery Packs

Table 1 Comparison of vibration test standards

3. Vibration Testing of Power Battery Systems

3.1 Vibration Table

Vibration testing is generally conducted using a vibration table, which can be mechanical, hydraulic, or electric. Electric vibration tables are the most widely used, with a broad working frequency range, good vibration waveform, and easy control and operation, generally meeting the requirements for vibration tests above 2Hz. The working principle of the electric vibration table is shown in Figure 1. Test conditions are set via computer control software, and the vibration controller sends drive signals to the power amplifier, which amplifies the signal and drives the vibration table to start vibrating. The acceleration sensor collects the vibration signals from the control point and feeds them back to the controller. The control software automatically adjusts the drive signal based on the feedback to ensure that the vibration load on the sample matches the target spectrum. Before conducting a vibration test, it is necessary to verify that the vibration table’s capacity meets the test requirements. The main parameters of the vibration table include maximum thrust, maximum acceleration, maximum speed, maximum displacement, and frequency range.

Vibration Testing for EV Battery Packs

Figure 1 Vibration Table Test Principle Diagram

3.2 Test Fixtures

Power battery systems are usually fixed to the vibration table using specially designed fixtures. The main function of the fixtures is to secure the sample to the table and transmit the vibration load from the table to the test sample without distortion. Therefore, the following requirements are placed on the fixtures used for power battery systems:

The fixtures should simulate the battery system’s installation state on the vehicle as closely as possible. The battery systems on vehicles are typically installed using flat, suspended, or press-fit methods. For example, battery systems used in electric buses and special-purpose vehicles are mostly standard box-type battery packs, usually laid flat on the chassis and secured with bolts. Most battery systems used in passenger vehicles are suspended from the chassis by lugs, while some quick-change battery systems are press-fitted onto the vehicle. Therefore, the fixture’s method of securing the battery system, bolt specifications, and torque requirements should match those of the actual vehicle to simulate the real load conditions.

Fixture stiffness and mass: The fixture for the battery system must have sufficient stiffness to ensure the vibration load is transmitted without distortion. At the same time, the fixture’s mass should be minimized as much as possible since excessive fixture weight can affect the vibration table’s load capacity and thrust. Therefore, appropriate materials and processes should be chosen for fixture manufacturing.

Fixture’s natural frequency: The first-order natural frequency of the fixture should be higher than the test frequency range to avoid resonance during vibration, which could affect the load on the sample. The fixture’s frequency response characteristics should be flat over the entire test frequency range, and resonance coupling between the fixture and the sample should be avoided.

Fixture’s lateral movement should be minimized.

3.3 Sensor Placement

The sensors used in vibration testing are generally divided into control points and monitoring points. The sensors at the monitoring points are only used for data monitoring, while the feedback data from the control point sensors⇱ are used to adjust the drive signal to ensure that the vibration level at the control point reaches the target value. Based on the number of control points, the test can be divided into single-point control and multi-point control. The control strategy in multi-point control can be based on the minimum value, maximum value, or arithmetic average value. Control points are usually located near the fixing points between the power battery pack and the fixture to accurately transmit the target vibration spectrum to the sample.

3.4 Test Monitoring

During the test, it is necessary to monitor the state of the battery pack in real-time, focusing on parameters such as maximum cell voltage, minimum cell voltage, maximum temperature, total voltage, and insulation status. If any critical parameters change, such as a voltage drop, the vibration should be immediately stopped to check the battery pack’s condition. Additionally, the battery pack’s external structure and vibration sounds should be observed during the vibration process.

3.5 Vibration Testing of a Power Battery System

In this study, a power battery system used in passenger vehicles was selected, and a random vibration test was conducted according to GB38031. Before the vibration test, performance tests, including capacity, insulation, and airtightness, were conducted on the battery pack. The vibration test was performed after confirming that all functions were normal. The battery pack was secured to the vibration table using fixtures, and the method of securing the battery pack and the bolt specifications were consistent with those used in the actual vehicle assembly. Control point sensors were placed near the bolts securing the fixture and the battery pack, with four sensors placed at diagonal positions for arithmetic average control. Sweep-frequency tests were conducted before and after random vibration to test the sample’s natural frequency. The sweep frequency ranged from 5 to 200Hz, with a sweep speed of 1Oct/min and a vibration level of 0.5g. Figures 2 and 3 show the sweep frequency data before and after Z-axis vibration, respectively. As shown in the figures, the first-order natural frequency before Z-axis vibration was 57.06Hz, and after vibration, it was 54.94Hz, with little change. According to GB38031, the sample underwent random and fixed-frequency vibrations in the Z, Y, and X directions, with the PSD of random vibrations in each direction shown in Figures 4 to 6. During the vibration test, the monitoring parameters of the battery pack showed no abnormal changes, and the appearance remained intact without any leaks or cracks. After the test, the battery pack underwent performance testing, with normal insulation, no significant change in capacity, and qualified airtightness, meeting the test requirements.

Vibration Testing for EV Battery Packs

Figure 3 Z-axis Vibration Post-sweep

With the formulation and implementation of the new GB38031 standard, the testing of power battery systems has been given a reasonable and standardized basis, ensuring that batteries are held to high safety and performance standards. At Bonnen Battery, we go beyond compliance by rigorously subjecting our power batteries to vibration testing in strict accordance with national guidelines. This thorough testing ensures that the batteries can reliably withstand the mechanical stresses and vibrations encountered during vehicle operation, thus maintaining optimal performance and longevity.

Our commitment to quality and safety reflects our dedication to delivering high-performance energy solutions that meet the evolving needs of the automotive industry. For more information or specific inquiries, please don’t hesitate to reach out to Bonnen Battery. Our team is always available to assist you with any questions or guidance on our battery systems.

| Shaker Model | JQA-202-335 JQA-203-335 |

| Frequency Range (Hz) | 5~3000 |

| Rated sinusoidal force (KN) | 20 |

| Shock force (KN) | 40/60✱ |

| Max. acceleration (m/s²) | 980 |

| Max. speed (m/s) | 2 |

| Max. displacement (mmp-p) | 51/76 |

| Max. load (kg) | 300 |

| Vibration isolation frequency(Hz) | 2.5 |

| Shaking table type | JQ-20 |

| Moving parts weight (kg) | 23 |

| Armature diameter (φmm) | 335 |

| Allowable eccentric moment (N x m) | 490 |

| Outer dimension (W·H·D) (mm) | 1080*990*860 |

| Shaker weight (kg) | 1600 |

| Power amplifier model | PA-20 |

| Max. output power (KVA) | 20 |

| Amplifier Size (W·H·D) | 550*1750*850 |

| Power amplifier Weight (kg) | 410 |

| Power Amplifier working model | Switch |

| System power consumption (KVA) | 40 |

| Cooling method | Forced air cooling |

| Fan model | FJ-3000 |

| Rated flow (m³/min) | 40 |

| Rated wind pressure (kPa) | 3.5/8.8 |

| Fan power (KW) | 7.5 |