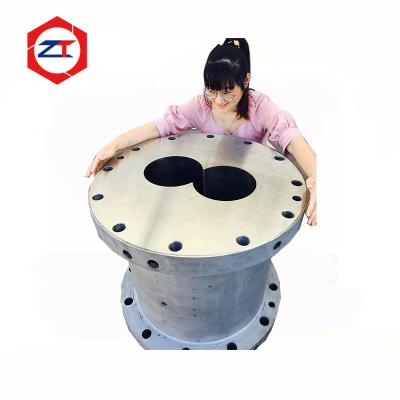

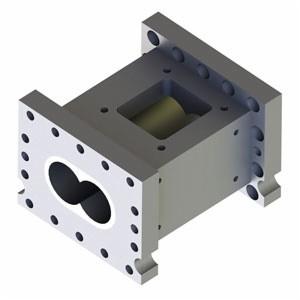

As a leading manufacturer of key components such as twin screw extruder gearboxes, barrels, screw elements, and core shafts on a global scale, our company has earned the trust of customers worldwide through exceptional quality and professional service.Our twin screw extruder gearboxes, known for their efficiency, stability, and durability, provide robust power solutions to customers across the globe. The unique design of our barrels ensures the stable operation of equipment, while our screw elements and core shafts, crafted with precision manufacturing processes, guarantee precise equipment performance.

Our products find extensive applications globally, ranging from the processing of high-molecular materials like plastics, rubber, and synthetic fibers to packaging in industries such as food, pharmaceuticals, and even emerging fields like lithium battery slurry coating for new energy sources. We consistently prioritize customer needs, offering personalized product designs and expert technical support to address practical challenges and create significant value.

Committed to continuous improvement in product quality and service standards, we strive for excellence to meet the evolving needs of our customers. We firmly believe that only through continuous innovation and enhancement can we maintain a leading position in the fiercely competitive global market.

We look forward to establishing long-term and stable partnerships with customers worldwide, collaborating to create a better future. If you have any questions or requirements regarding our products or services, please feel free to contact us at any time.