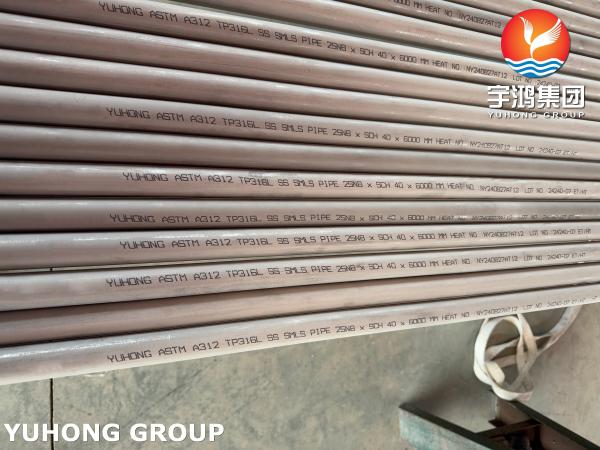

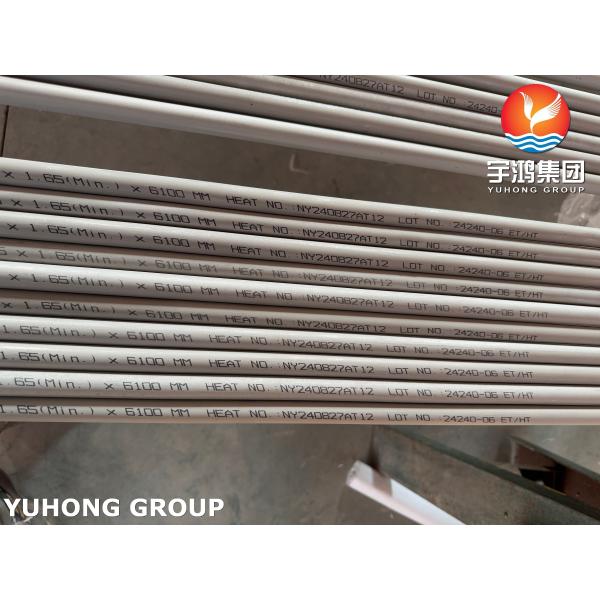

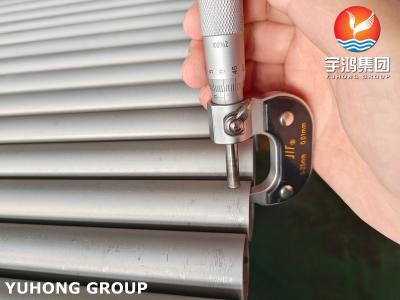

ASTM A269 TP316L seamless tubes are high-quality stainless steel tubes designed for exceptional corrosion resistance and strength in various environments. Made from low carbon 316L stainless steel, they are ideal for applications in the oil and gas, marine, food processing, and pharmaceutical industries. The lower carbon content minimizes the risk of carbide precipitation during welding, enhancing their durability. These tubes offer good mechanical properties, excellent weldability, and resistance to pitting, making them suitable for high-temperature and corrosive conditions. Their seamless construction ensures uniformity and reliability, making them a preferred choice for demanding applications.

Apparel & Textile Machinery

(75900)

Building Material Machinery

(55852)

Cleaning Equipment

(104054)

Electronics Production Machinery

(39881)

Energy & Mineral Equipment

(127869)

Engineering & Construction Machinery

(401378)

Environmental Machinery

(35590)

Food & Beverage Machinery

(97353)

Industrial Compressors & Parts

(28499)

Industrial Robots

(3603)

Industry Laser Equipment

(44115)

Machine Tool Equipment

(129643)

Machinery Accessories

(202994)

Machinery Service

(996)

Metal & Metallurgy Machinery

(69132)

Packaging Machine

(102444)

Paper Production Machinery

(29371)

Language

Français

Русский язык

Español

日本語

Português

Show all machinery categories

Apparel & Textile Machinery

(75900)

Building Material Machinery

(55852)

Cleaning Equipment

(104054)

Electronics Production Machinery

(39881)

Energy & Mineral Equipment

(127869)

Engineering & Construction Machinery

(401378)

Environmental Machinery

(35590)

Food & Beverage Machinery

(97353)

Industrial Compressors & Parts

(28499)

Industrial Robots

(3603)

Industry Laser Equipment

(44115)

Machine Tool Equipment

(129643)

Machinery Accessories

(202994)

Machinery Service

(996)

Metal & Metallurgy Machinery

(69132)

Packaging Machine

(102444)

Paper Production Machinery

(29371)