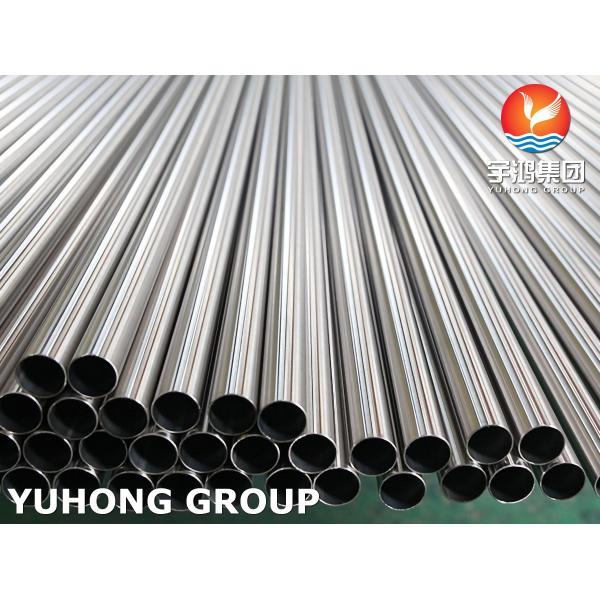

ASME SA249 TP316 Stainless Steel Welded Tubes Bright Annealed Mirror Polished

Yuhong Special Steel has been engaged in the operation of seamless welded pipes and pipes of austenitic stainless steel, nickel alloy steel (Hastelloy, Monel, Inconel, Inconel) for more than 25 years, and annual sales of more than 80,000 tons of steel pipes and pipes. Our customers have covered more than 45 countries including the United States, Canada, Italy, the United Kingdom, Germany, Chile, Colombia, Saudi Arabia, South Korea, Singapore, Australia, Poland, and France.

Compared with traditionally used chromium-nickel steel, marine grade SA 249 Tp316 has excellent corrosion resistance, especially during exposure to corrosive compounds. One reason the stainless steel 316 Erw is considered superior to the chromium-nickel steel grade is the addition of chromium to its alloy. Although similar to austenitic alloy 304, 316 stainless steel welded pipes are much more resistant to sea water and saline solutions. Therefore, welding 316 stainless steel pipe is synonymous with offshore engineering applications.

In addition, in addition to solutions containing sulfuric acid, ASTM A249 TP316 tubes can also tolerate halides such as chloride, bromide, and iodide. ASTM A249 TP316 welded boiler tubes are also resistant to fatty acids at high temperature settings. In addition, SA-249 TP316 will not lose its mechanical properties when used in a wide temperature range. Because the alloy is non-toxic, A249 TP316 welded pipe is usually used in industries with zero tolerance for pollution. For example, the textile, pharmaceutical, and food and beverage industries prefer to use ASME SA 249 TP316 because it has no pollution characteristics.

Standard Specification:

ASME SA249 316 Stainless Steel Tubing Specification

| Specification | ASTM A249 TP 316 Stainless Steel Welded Superheater, Condenser, Hydraulic, Boiler and Heat-Exchanger Tubes |

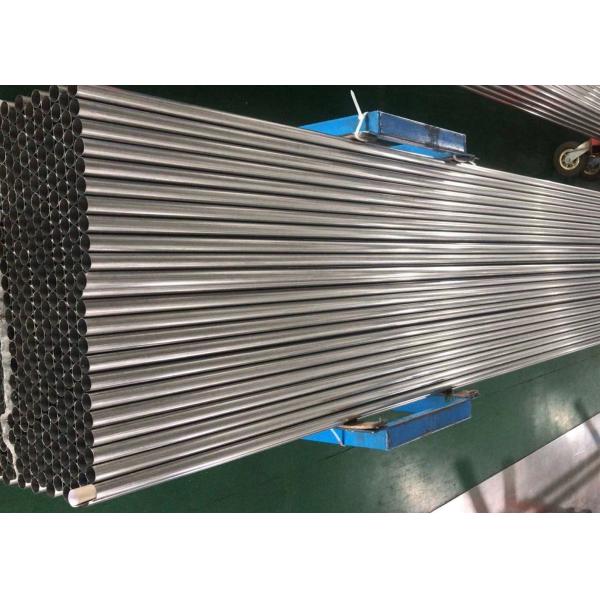

| Shapes | ASME SA249 316 Stainless Steel Round, Rectangular, Square, Hydraulic, Straight, U Bend Tube, Coiled, Honed Tubes, Pan Cake Coils |

| Manufacturing Type | Welded / Fabricated / ERW / CDW / DOM / CEW / 100% X Ray Welded |

| Delivery Condition | Annealed and Pickled (AP), Polished, Bright Annealed (BA), Cold Drawn, MF |

| Surface Finish | BA, 2B, No.4, No.1, No.3, No.8, 8K, HL, 2D, 1D, Mirror Polished, 180G, 320G, 400G Satin/ Hairline, 400G, 500G, 600G or 800G Mirror finish ASME SA249 316 Standard Tubing or Custom Finish as per customer's specification |

| OD | 25.4, 16, 190.5, 31.8, 44.45, 38.1, 50.8, 60.3 mm |

| WT Thickness Range | 1.65, 1.0, 0.71, 0.89, 1.25, 1.5, 2.11 mm |

| Standard | SUS, JIS, AISI, ASTM, GB, DIN, EN |

| Value Added Services | - Cutting

- Beveling

- Threading

- Polishing (Electro & Commercial)

- Draw & Expansion as per required Size & Length

- Destructive and Non Destructive

- Ultrasonic Testing

- Annealed & Pickled Bending

|

| END | Plain End, Beveled End, Treaded SS SA 249 UNS S31600 Tube |

| Processing Service | Bending, Welding, Decoiling, Punching, Cutting, Moulding |

| Technique | 316 Stainless Steel ASTM A249 Cold drawn, Cold rolled, Hot rolled, Extrusion Tube |

| Test Certificate | - Fumigation Certificates

- Heat Treatment Charts

- HS Code Commercial Invoice

- Form A for Generalized System of Preferences (GSP)

- DFARS compliant

- EN 10204/3.1B, EN 10204 3.1 and EN 10204 3.2 Material Test Certificates (MTC)

- 100% Radiography Test Report

- Raw Materials Certificate

- Third Party Inspection Report

- Surface roughness measurement

- Manufacturer Test Certificate

- Laboratory Test Certificate from Govt. Approved Lab

- Moisture testing

|

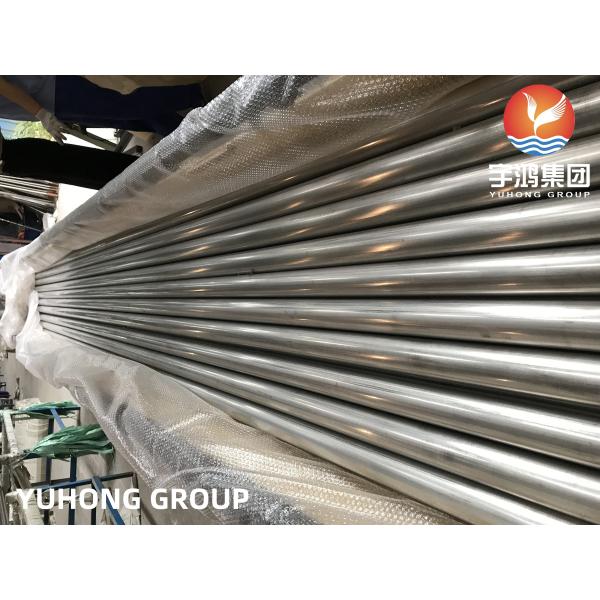

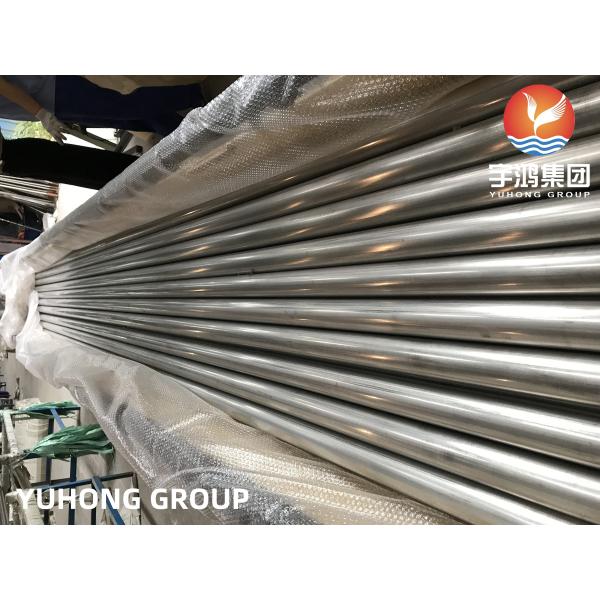

| ASTM A249 316 Welded Austenitic Steel Tubing Packaging | Packed in PE Fabric Bundles or ply wooden box wrapped in plastic or Standard seaworthy export packing or as per customers' request |

| Origin | China |

| Uses & Application | - Common industrial services (Petroleum, chemical, paper, fertilizer, fabric, aviation and nuclear)

- Fluid, gas and oil industry

- Heat transmission and pressure service

- Construction and ornamental

- Boilers and Heat exchangers

- Decoration purpose, boiler, auto parts, medical device, food industry, building materials)

|

316 Stainless Steel ASTM A249 Tubing Mechanical Properties

| SA 249 | TENSILE STRENGTH(MPA) | YIELD POINT(MPA) | ELONGATION(%) | HARDNESS (HRB) |

| 316 | 515 | 205 | 35 | 95 |

ASTM A249 316 Welded Austenitic Steel Tube Chemical Composition

| AISI | C | MN | P | S | SI | NI | CR | MO | TI | N |

| 316 | 0.08 | 2.00 | 0.045 | 0.030 | 1.0 | 11-14 | 16-18 | 2-3 | | |

ASME SA 249 TP 316 Equivalent

| ASME SA 249 | UNS | WNR. / DIN | JIS | AFNOR | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 | GOST | EN |

| TP 316 | S31600 | 1.4401 / 1.4436 | SUS 316 | Z7CND17‐11‐02 | 316S31 / 316S33 | - | |