Apparel & Textile Machinery

(75900)

Building Material Machinery

(55852)

Cleaning Equipment

(104054)

Electronics Production Machinery

(39881)

Energy & Mineral Equipment

(127869)

Engineering & Construction Machinery

(401378)

Environmental Machinery

(35590)

Food & Beverage Machinery

(97353)

Industrial Compressors & Parts

(28499)

Industrial Robots

(3603)

Industry Laser Equipment

(44115)

Machine Tool Equipment

(129643)

Machinery Accessories

(202994)

Machinery Service

(996)

Metal & Metallurgy Machinery

(69132)

Packaging Machine

(102444)

Paper Production Machinery

(29371)

Language

Français

Русский язык

Español

日本語

Português

Show all machinery categories

Apparel & Textile Machinery

(75900)

Building Material Machinery

(55852)

Cleaning Equipment

(104054)

Electronics Production Machinery

(39881)

Energy & Mineral Equipment

(127869)

Engineering & Construction Machinery

(401378)

Environmental Machinery

(35590)

Food & Beverage Machinery

(97353)

Industrial Compressors & Parts

(28499)

Industrial Robots

(3603)

Industry Laser Equipment

(44115)

Machine Tool Equipment

(129643)

Machinery Accessories

(202994)

Machinery Service

(996)

Metal & Metallurgy Machinery

(69132)

Packaging Machine

(102444)

Paper Production Machinery

(29371)

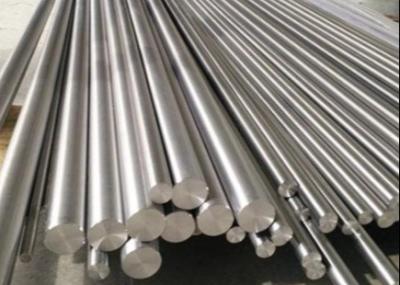

1,Titanium Forging Application 1. Aerospace Aircraft structural components Jet engine components: fan blades, housings, disks, compressor blades, disks, short shafts, housings Spacecraft components: blades for fuel tanks, attitude control engine housings, liquid fuel turbopumps 2. Turbine blades for power generation 3. Medical field Implants: joint replacements (hip and knee implants), spinal implants and fixation devices Surgical instruments: for the manufacture of surgical tools, forceps and scalpels 4. Automotive High-performance engine components: connecting rods, crankshafts Suspension systems 5. High-end equipment manufacturing High-speed rail and rail transportation Large machine tools and precision machinery 2.Product Details

1,Titanium Forging Application 1. Aerospace Aircraft structural components Jet engine components: fan blades, housings, disks, compressor blades, disks, short shafts, housings Spacecraft components: blades for fuel tanks, attitude control engine housings, liquid fuel turbopumps 2. Turbine blades for power generation 3. Medical field Implants: joint replacements (hip and knee implants), spinal implants and fixation devices Surgical instruments: for the manufacture of surgical tools, forceps and scalpels 4. Automotive High-performance engine components: connecting rods, crankshafts Suspension systems 5. High-end equipment manufacturing High-speed rail and rail transportation Large machine tools and precision machinery 2.Product Details

4,Product Features High strength Corrosion resistance High fatigue and impact resistance Thermal Stability. Titanium has a melting point of 1,668°C (3,034°F) 5,Mechanical/Mechanical Properties of Titanium forging

4,Product Features High strength Corrosion resistance High fatigue and impact resistance Thermal Stability. Titanium has a melting point of 1,668°C (3,034°F) 5,Mechanical/Mechanical Properties of Titanium forging