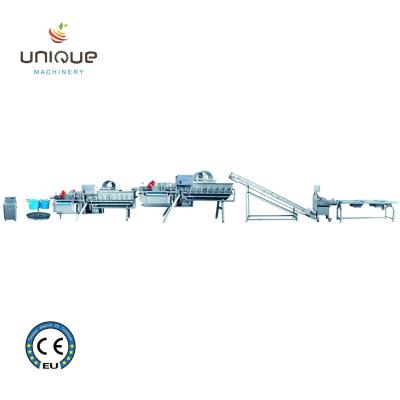

1. Food grade 304 stainless steel.

2.Spraying nozzles on upside of peeling drum to clean vegetables.

3. Equipped with food grade hard nylon brush to polish the surface of vegetables.

4. Optional abrasive roller is available. Special for improving peeling speed or peeling thick-skinned vegetables, such like

cassava.

5. Adjustable speed auger/screw in the peeling drum to push vegetables move forward.

6. Filter screen to collect waste impurity after peeling and drain water separately.

2.Spraying nozzles on upside of peeling drum to clean vegetables.

3. Equipped with food grade hard nylon brush to polish the surface of vegetables.

4. Optional abrasive roller is available. Special for improving peeling speed or peeling thick-skinned vegetables, such like

cassava.

5. Adjustable speed auger/screw in the peeling drum to push vegetables move forward.

6. Filter screen to collect waste impurity after peeling and drain water separately.