RAL 2000 Orange Peel Wrinkle Texture Powder Coating for Hardware Tool

WhatsApp:+86 18190826106

Wrinkle texture powder coatings, by combining aesthetics and functionality, have become an ideal choice for many industrial and consumer fields, especially suitable for scenarios where substrate defects need to be concealed or special styles are pursued

Thermosetting powder coating is a very popular method of painting parts, available in a wide range of finishes and colors. Rapid-coat powder coatings produce a long-lasting, aesthetically pleasing finish with a range of advantages over traditional painting methods, from environmental impact to cost.

more details contact us:

Whatsapp/wechat : +86 18190826106

email.:esu.sales7@hsindapowdercoating.com

Product Description

♦Epoxy powder coating: offer the best corrosion protection.

♦Polyester powder coating: offer the highest exterior stability and performance.

♦Our products applied to indoor and outdoor.

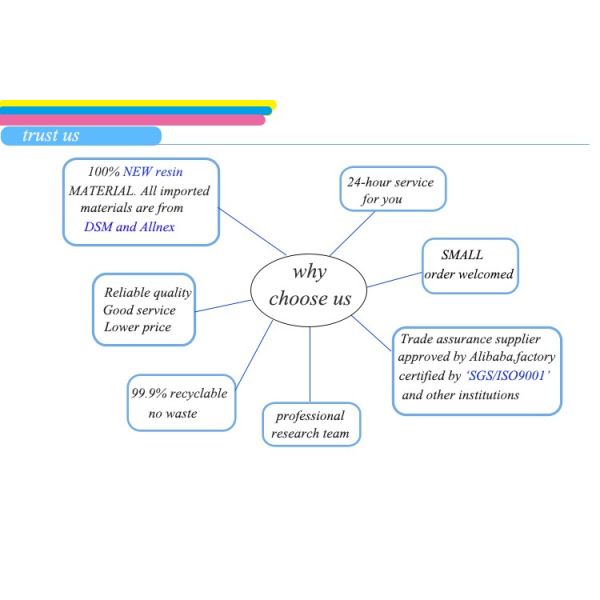

Hsinda Powder coating powder manufacturer, factory direct.

RAL/Pantone chart, color customization

Competitive price, personalized terms, fast shipping, ISO, ROHS, REACH certification

Export to 70+ countries,

Powder coating is a new type of 100% solid powder coating which does not contain solvents. With no solvent, no pollution, energy and resources saving, recycling, environmental protection, higher performance, low hehigh gloss mirror chrome sliver spray paint powder coatingh risk to workforce, economical advantages etc.

Most powder coating is used by electrostatic spraying on metal surface, and then cure in oven, eventually form a solid layer.

Powder Types & Application Table

The powders most commonly used in the Powder Coating Industry are epoxy, polyesters, nylon, PVC, and to a lesser extent polyurethane and acrylic. There is also a Hybrid, an epoxy/polyester mix that is also often used.

We at Woncheng use mainly epoxy, polyester and epoxy/polyester. These three types of powder cover most of our customers application requirements.

Product overview

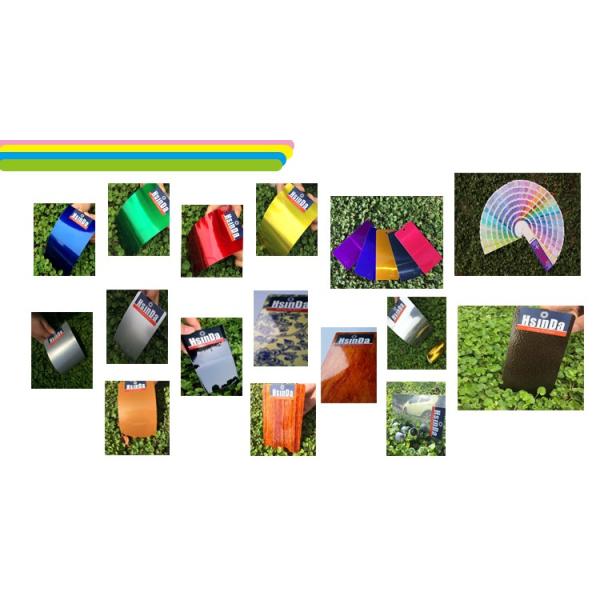

Other product

- Our Powder finishes are available in a vast range of colors and finishes.

- Including metallic effect,chrome effect,wood grain,Candy Color Powder ,MDF powder

- and other special effect,making them ideal for indoor decoration of steel furniture,

- and outdoor metal products such as agricultural machinery, auto parts

product detail

| Type | Epoxy Powder Coating; Polyester Powder Coating; Epoxy-Polyester Powder Coating |

| Color | Ral&Pantone color |

| Surface Finish | Superior gloss and color retention |

| Particle Size | Average 32-42μm |

| Specific Gravity | 1.2-1.7g per cubic meter |

| Coverage | 8-10 square meters per Kg at 30-90 μm film thickness |

| Film thickness | Not less than 100μm |

Instruction

| Application Voltage | 60-90 KV |

| Gun to Component Distance | 15-30CM |

| Curing Temperature | 180-200℃,10 min-15 min |

Storage stability

| Store in ventilated, dry, clean room, temperature < 25℃ | Relative humidity 50-65% |

| Away from direct sunlight, fire, heat | For best performance, use within 6 months |

Product process

- Powder coatings are based on Resin,Pigments,Curing Agents,Additives.

- Resin(including Epoxy, polyester, hybrid)giving the basic performance to the coating.

- Pigments, Providing the colour and effects, such as metallic or hammer.

- Curing Agents, reacts with the resin to form a continuous protective film.

- Additives, can be used to promote variations in the performance or surface effects.

2.Trade items of Products

| Trade terms | FOB, CIF,CRF,CNF |

| Payment terms | T/T, L/C , West Union ,Moneygram , Paypal etc |

| Payment condition | 30% deposit in advance,70% balance before shipment |

| Delivery time | 3-7 days after deposit |

| Shipping | By sea, by air and by express delivery |

| Sample Powder will be delivery by courier ,like DHL,UPS,FEDEX etc. 5-8 DAYS to arrival |

| Official Order Powder will be ship by SEA .15-30 DAYS to arrival |