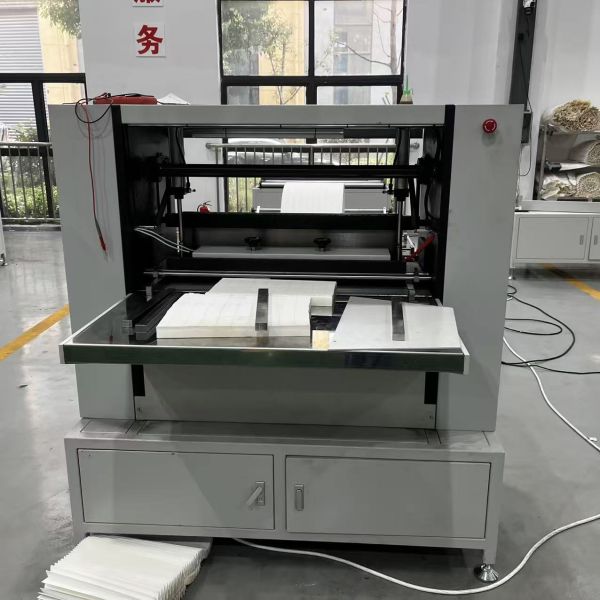

2 Generation pleating machine

Industrial filter element pleating machine - accurate and efficient, enabling intelligent creation of a new future.

Precision pleating, quality choice Industrial filter pleating machine, designed for efficient filter production! Advanced numerical control technology is adopted to achieve the accuracy of **±0.1mm micron level **, ensure that each fold is uniform and dense, and greatly improve the filtration efficiency and service life of the filter element. Whether it is PP melt-blown or composite filter material, it can be easily handled to help create industrial filter products with high precision and high stability

Core advantages, intelligent manufacturing upgrade

✅ Efficient production

pleating design, speed up to 60folds/min (adjusted according to actual parameters), production capacity increased by 300%, to meet the needs of bulk orders.

✅ Stable and durable :

high strength alloy body, core components imported configuration, 7×24 hours continuous operation without pressure, failure rate is lower than the industry standard.

✅ Energy Saving and Environmental protection :

Low power motor + intelligent start-stop technology, energy consumption is reduced by 40%, green production saves costs.

Widely used, covering the whole field ** ✔ Petrochemical: high temperature and corrosion resistant filter element manufacturing ✔ Food and medicine: aseptic high precision filtration solution ✔ Environmental protection water treatment: ultra-long life industrial filter element customization ✔ Automotive industry: Efficient production of air filters and fuel filters