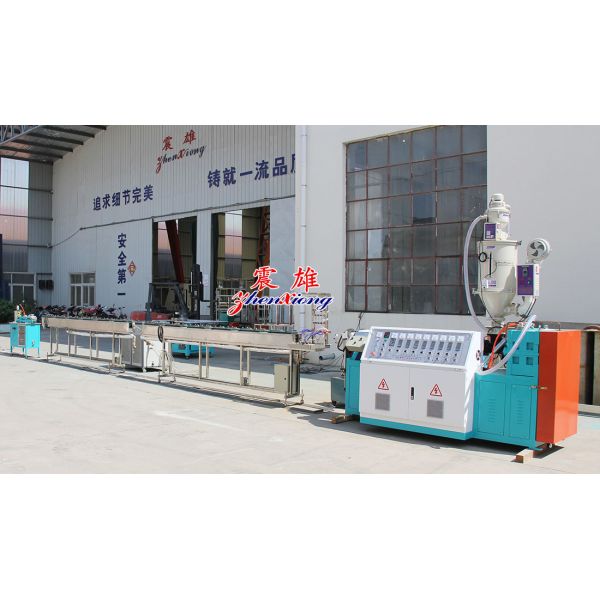

PVC Refrigerator Freezer Door Gasket Production Line Semi Automatic Good Gasket Quality

Our company is a professional manufacturer of refrigerator door seal production line, with more than 20 years of production and development experience.

The semi-automatic refrigerator door seal production line is composed of extruder, head mold, cooling sink and traction cutting machine. At the same time, it has the high efficiency of mechanization and the flexibility of manual operation, and can be flexibly adjusted according to different production needs to improve production efficiency.

Core advantages:

●The semi-automatic refrigerator door gasket production line adopts SJ75 extruder, equipped with PVC professional separation screw, with high production capacity and good material plasticization effect.

●The head mold of the semi-automatic refrigerator door gasket production line is made of 40Cr mold steel material, quenched, tempered and forged, with high strength, wear resistance, and mold accuracy.

●The semi-automatic refrigerator door seal production line is equipped with 5P air-cooled chiller, the products are fully and quickly cooled, and the cooling water temperature can be manually adjusted and controlled according to needs.

●The semi-automatic refrigerator door gasket production line is equipped with an automatic drying and feeding machine, which automatically alarms for overload and shortage, reducing labor costs;

●The semi-automatic refrigerator door gasket production line has two cooling water tanks, each section is 4 meters long, and the cooling water path is long. It adopts circulating water spray cooling, which is fast and uniform, and the product shaping effect is good.

●The semi-automatic refrigerator door gasket production line automatic cutting device can achieve high-precision fixed length cutting.

Product application scope:

The door seal products produced by the semi-automatic refrigerator door gasket production line have a smooth surface without burrs, strong elasticity, uniform thickness, wear resistance, high and low temperature resistance, high and low temperature resistance, and are not easily aged or deformed after long-term use. Widely used in various refrigerators, freezers, water dispensers, beverage cabinets, disinfection cabinets, kitchenware, profile doors and windows, as well as various daily products and other industrial products.

| Weight | 1.5 T | Capacity | 8 - 15/minute |

| Power Consumt | 22 KW | Operating Mode | Semi - Automatic |

| Voltage | 220V 380V / Customized | Dimensions | 1500x1600x1800mm |