Drilling and tapping machine

The machine tool adopts PLC system control and hydraulic transmission, with simple and fast operation. It can simultaneously process two flange drilling and middle head drilling threads. Fast speed, improved processing efficiency, saved labor, and reduced costs.

Main features

1. High processing efficiency:the machine tool uses three power heads to work simultaneously during the machining process, which can complete the machining of three flat drilling holes and mid head tapping threads at the same time.

2. Reducing manual labor: means combining a double-sided porous drill and a mid head drilling and tapping machine to clamp workpieces in one go, processing both flanges and mid heads simultaneously. This not only improves efficiency but also reduces clamping times, and one person can operate 2-3 specialized machines.

3. The uniformity of machining dimensions is high, and this special machine is completely controlled by a PLC system with dedicated tooling positioning. Only one tool alignment is needed to repeatedly machine the same type of workpiece, thereby improving the uniformity of dimensions.

4.Easy to operate, this special machine adopts PLC and travel switch control, which is easy for those with experience in organic operation or basic organic processing to learn.

Main components

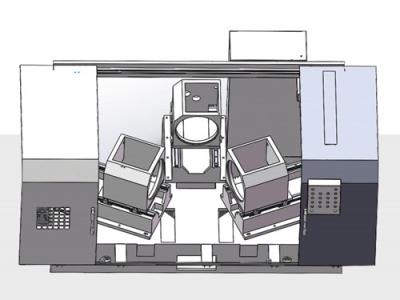

This machine tool is controlled by a hydraulic system and consists of two porous drilling power heads and a movable fixture.

Application

The machine tool is suitable for processing gate valves, water conservancy valves, etc. that require drilling at both ends and threading at the middle end.

Specifitions

| Project | Machine tool specification | YC lll ZG200HT | YC lll ZG400HT |

| Technical specifications | Maximum drilling center distance (mm) | φ295 | φ525 |

| Maximum processing length (mm) | 600 | 700 | |

| Minimum processing length (mm) | 200 | 300 | |

| Maximum machining size from middle flange to center (mm) | 300 | 400 | |

| Minimum machining size from middle flange to center (mm) | 150 | 150 | |

| Journey (mm) | 345/300 | 430 | |

| Drill bit connection method | Mo style taper handle 2 #/ER chuck | Mo style taper handle 2 #/Mo style 3 #/ER chuck | |

| Machining accuracy | Position tolerance of flanges on both sides (mm) | ≤0.5 | ≤0.5 |

| Position tolerance of middle flange (mm) | ≤0.5 | ≤0.2 | |

| Surface roughness | 12.5 | 12.5 | |

| Main shaft drive | Transmission form (gear shifting) | 2-speed transmission | 2-speed transmission |

| Spindle speed range (r/min) | 225/286 400/100 | 159/231 400/100 | |

| Middle flange spindle motor model | YE2-132M-6-2.2KW | YE2-132M-6-3.7KW | |

| Two end flange spindle motor model | YE2-132M-6-5.5KW | YE2-132M-6-5.5KW | |

| Numerical Control System | PLC | ||

| Feed form | Hydraulic transmission Cylinder transmission | ||

| Machine tool appearance | Machine tool external dimensions (Length X Width X Height mm) | 2800X2400x1500 | 3300X2600X1600 |

| Machine weight (kg) | 3500 | 4000 | |

Processed products